The trip to Sweden wasn’t just about teaching or sightseeing. It was about connection. And on this final leg, I was lucky enough to join a study tour to Lund, organised by Business Sweden, focused on sustainable heating and cooling in practice.

Coincidentally, it came just after my week teaching at KTH — a perfect bookend to a week that began with theory and ended with real-world innovation.

🏭 Kraftringen: 4G District Heating, Net Zero by 2030

We started at Kraftringen, a regional energy provider delivering electricity, heating, cooling, and fibre internet across southern Sweden.

“In Sweden, electricity is 140 TWh, heat is 100 TWh — but there’s no market for heat.”

— Sezgin Kadir, Group CEO, Kraftringen

That sentence stuck with me. It’s a system that works — but one that’s still disconnected from the market economy. Yet, Kraftringen is pushing forward:

- Net zero CO₂ emissions by 2030

- 4G district heating system

- A major demonstration project: Brunnshog, where recycled residual heat will become district cooling — set to launch Q1 2026, with a first-phase investment of 200 million SEK

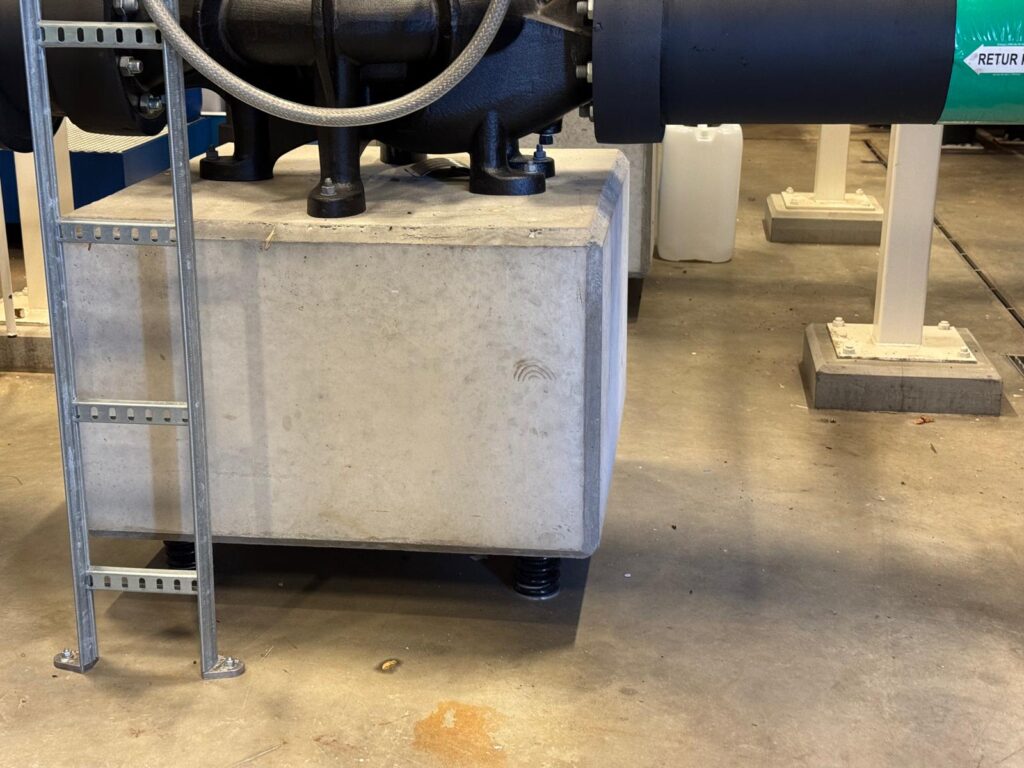

We saw the spring systems supporting compressors — designed to reduce vibrations across the entire building. Small detail. Big impact.

🌐 E.ON Ectogrid: 3 Global Demonstrations, One Vision

Next stop: E.ON Ectogrid, a pioneer in smart, flexible district energy systems.

They’re running three live demonstrations — each tackling heat decarbonisation differently:

- Medicon Village, Lund, Sweden

- Type: Balanced energy

- Size: 16 GWh demand, 23 buildings

- Source: Air-to-water heat pumps

- System: 5G district heating and cooling

- Silvertown, London, UK

- Type: Waste heat

- Size: 40 GWh, 6,500 apartments

- Source: Industrial waste heat

- Magasins Généraux, Reims, France

- Type: Ambient heat

- Size: 6 GWh, 400 apartments

- Source: Geothermal

We visited the Medicon Village site — a living lab of efficiency. The large thermal storage tank stood out: a quiet, massive presence, storing heat for when it’s needed most.

🏭 Alfa Laval: Where Heat Exchangers Are Engineered, Not Just Built

The final stop was Alfa Laval’s heat exchanger manufacturing facility — a vast, high-tech site where innovation is built into every component.

I hadn’t realised the depth of R&D behind a single heat exchanger. With hundreds of patents, this isn’t just a factory — it’s a research hub.

The scale was impressive. The precision, staggering. And the quiet hum of a system designed to move heat with maximum efficiency? That’s the future.

🌆 A Final View: Lund from the Rooftop

We ended day 1 at a rooftop bar in Lund — a quiet moment to reflect.

The city stretched below, bathed in golden light. The air was cool. The conversation, still buzzing with ideas.

✈️ The Last Word: “Time flies when you’re exploring the world”

As I boarded my flight from Copenhagen Airport, I passed a the followign sign:

It felt like the perfect closing line.

Ten days in Sweden — a week teaching at KTH, a study tour in Lund, meetings, labs, sadya, chaat, golden halls, and midnight walks.

I came for energy systems. I left with ideas, connections, and a renewed sense of what’s possible.

And one clear takeaway:

Heat decarbonisation isn’t just about technology. It’s about systems, markets, and the courage to pilot what’s next.

The UK has much to learn — and much to offer.